TUNGSTEN ALLOY CNC MACHINING

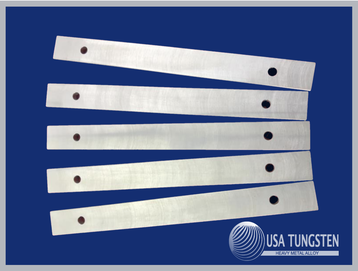

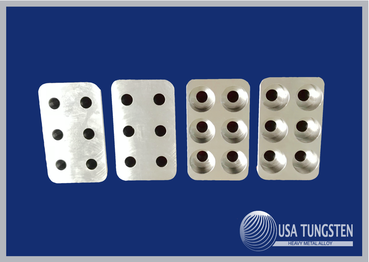

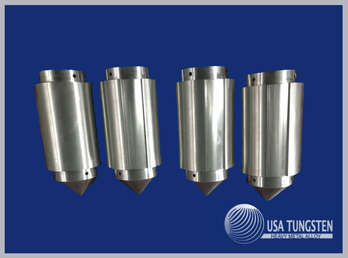

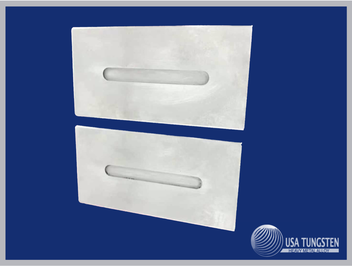

USA Tungsten provides CNC machining service that meets any complex design specifications. It encompasses turning, milling, drilling and tapping of Tungsten Alloy. We analyze your design and accommodate any special fixturing and machining strategies used to produce your parts at a very reasonable cost.

TUNGSTEN ALLOY CNC MACHINING

|

Axis CNC Milling Capabilities

When mentioned a standard 5-axis machine, it refers to the number of directions in which the cutting tool can move, that after setup the cutting tool moves across the X, Y and Z linear axes and rotates on the A and B axes, simultaneous milling and machining, and with high-quality surface machined finish. This allows the complex and intricate parts or parts featuring multiple sides can be processed up to five sides of a part in a single setup. This supports design engineers to design multifaceted parts with tight tolerances that can enhance the functionality and performance of the final product without limited process. As many parts produced in prototype shops require five-sided machining, 5-axis milling and machining services are in high-demand for various applications in a wide range of industries including aerospace industry, steamer industry, car refitting industrial as well as energy production industries. Machining benefits include higher-quality surface finish, positioning accuracy, and short lead time while creating a tremendous edge for new business opportunities. |

|

Advantages of 5-axis CNC milling

High-quality surface finish: It is feasible to produce high-quality machined finish parts with the use of shorter cutters with a higher cutting speed, which can reduce the vibration that frequently occurs when machining deep cavities with a 3-axis process. It makes a smooth surface finish after machining.

Positioning accuracy: 5-axis simultaneous milling and machining has become crucial if your finished products must adhere to strict quality and performance standard. 5-axis CNC machining also eliminates the need to move the work piece among multiple workstations, thereby reducing the risk of error.

Short lead times: The enhanced capabilities of the 5-axis machine results in decreased production times, which translate into shorter lead times for production compared to the 3-axis machine.

High-quality surface finish: It is feasible to produce high-quality machined finish parts with the use of shorter cutters with a higher cutting speed, which can reduce the vibration that frequently occurs when machining deep cavities with a 3-axis process. It makes a smooth surface finish after machining.

Positioning accuracy: 5-axis simultaneous milling and machining has become crucial if your finished products must adhere to strict quality and performance standard. 5-axis CNC machining also eliminates the need to move the work piece among multiple workstations, thereby reducing the risk of error.

Short lead times: The enhanced capabilities of the 5-axis machine results in decreased production times, which translate into shorter lead times for production compared to the 3-axis machine.

Our goal is to provide you with the

HIGHEST QUALITY TUNGSTEN PRODUCTS!!

HIGHEST QUALITY TUNGSTEN PRODUCTS!!